Stegman Inspection Services provides comprehensive dimensional inspections on your parts to assure their compliance with the design specification. Whether it is a Supplier Quality Verification or a Third Party Verification requirement, we have the expertise to give you accurate results.

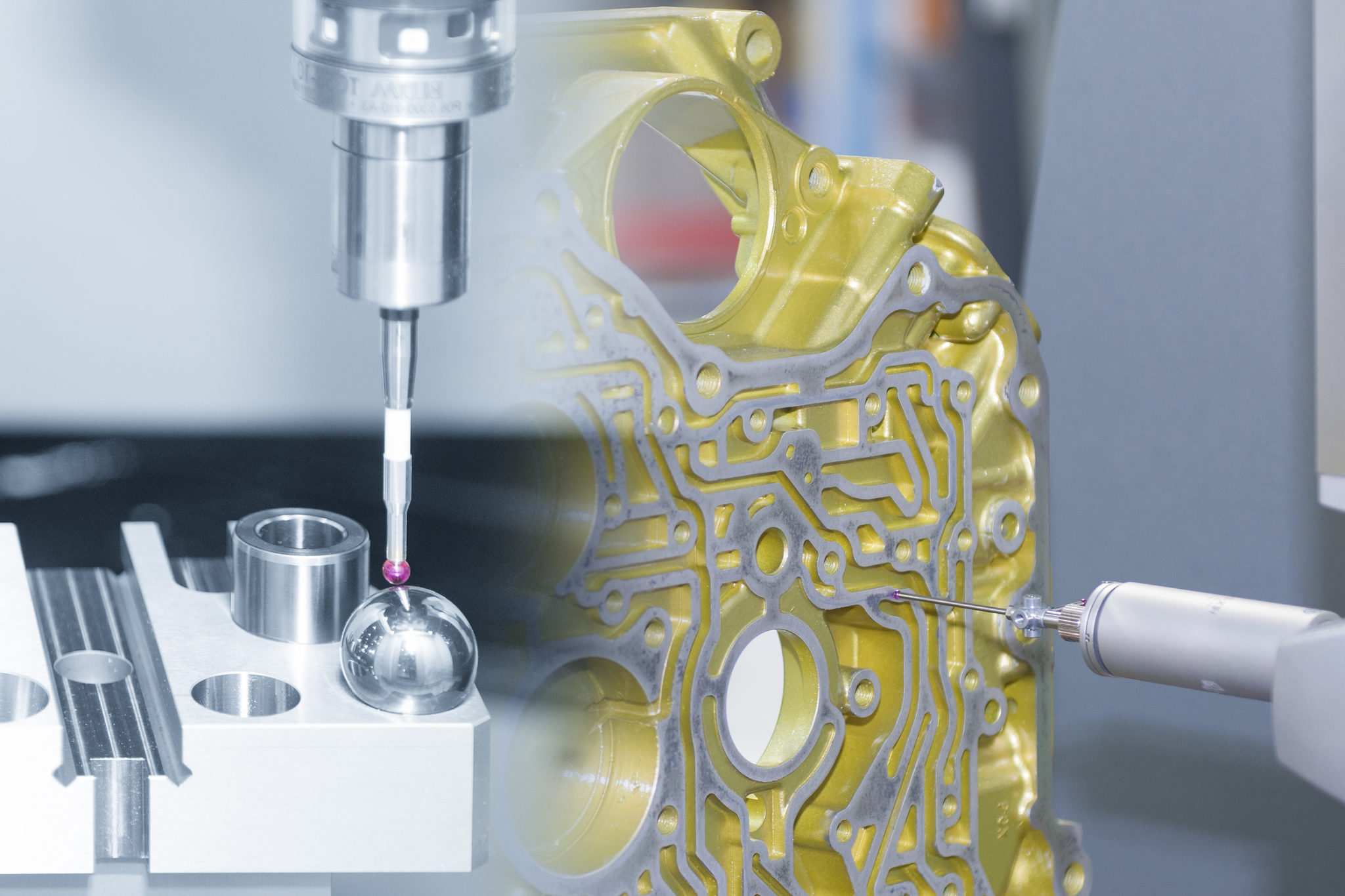

Our Zeiss CMM performs touch probe scanning of your product with the utmost precision. The probe and styli travel all around and inside the object being inspected, gathering data from every angle through direct contact with the product. This method provides a quick, efficient, and accurate dimensional measurements.

We provide a variety of inspection services depending on your requirements:

- First Article Inspection – First piece inspections are performed to assure your manufacturing process is producing a conforming part, but also lets you refine your process to its utmost output. Our FAI inspections are fast and highly accurate so you can get back up and running quickly.

- Quality Control Inspection/In-Process Inspection – Periodic inspections to verify production parts are meeting design and functionality requirements are necessary. Our quick turnaround will keep you producing quality parts and your production lines and/or CNC machines up and running.

- Final Inspection – Whether it is verification of your completed manufacturing run or a sample lot of the finished product, let us give you peace of mind that the product is meeting design compliance before going to market.

- System 22 Thread Inspection – Have very critical threads that require inspection to ASME B1.3, FED-STD-H28/20B, or SAE-AS-8879? Let Stegman Inspection Services examine conformance of a product thread for both functional and pitch/groove diameter. Also, the inspection examines that the combined effects of variations in lead, flank angle, circularity (roundness), taper, and runout are within limits.

Stegman Inspection Services provides detailed inspection reports with all orders. Other requirements can be detailed as well, such as serialization, climate, and conformance sorting/identification.